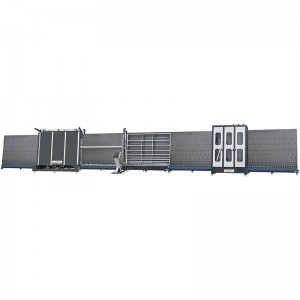

Eight Point Welding Machine WDCNC-SHP8W-CNC- 3000B

Eight Point Welding Machine WDCNC-SHP8W-CNC- 3000B

Main Features

1.Welding heads adopt special rigidity design with compact structure to increase the welding range and suitable for the complex window production mode.

2.Horizontal structure with strengthened rigidity design for stable operation. The moving part of welding heads adopt linear bearing motion guide to ensure the high precision of the finished frame.

3.Adopts particular surface positioning system which can ensure the high welding precision.

4.Unique know-how which increases the strength of the welded corners.

5.Heating time starts when the heating plates reach at the right position, which meet the criterion of European welding.

6.Automatic positioning for four types of profiles on V welding machine heads. Easy to adjust.

7.2mm general welding and 0.2mm seamless welding are adjustable.

8.Teflon could be changed with the roller device to shorten the changing time.

9.Controlled by seven- -axis CNC system which can compensate the tolerance of the size,and increase the precision of the welding size

10.The whole machine adopts high quality electric, pneumatic and mechanic parts which make it more reliable.

11.With high speed automatic conveying system to increase the production efficiency.

12.Worktable and the height of machine body are designed by ergonomic principles to reduce labor intensity

13.17-inch super- -large control screen with graphical interface for simple and intuitive operation.

Main Parameter

| Input Voltage | 3P 380V 50Hz |

| Input Power | ≈16.5KW |

| Air Pressure | 0.5~0.7MPa |

| Air Consumption | ≈150L ./min |

| Welding Height | 35~120mm (Mullion Welding: 55 ~ 120mm) |

| Welding Width | Corner Welding: 120mm Mullion Welding: 120mm |

| Welding Range | 480mm x 950mm ~ 1800mm x 3000mm |

| Overall Dimension | 4000mm x 7700mm (including conveying table: 3200 x 2000mm) |

| Weight | ≈4000kg |